Introduction: A Modern Manufacturer with a Legacy of Excellence

For over 40 years, GH Tool & Mold has been a trusted leader in high-pressure die cast tooling. Known for precision engineering and a relentless focus on quality, GH has earned its reputation by constantly evolving.

But as with many small-to-mid-size manufacturers in high-mix, low-volume environments, they began to hit limits – not in their expertise, but in their ability to scale knowledge, track processes, and make improvements stick.

Their solution? Implementing JobTraQ, a no-code workflow automation platform built specifically for manufacturers like GH.

The result? A system that touches every corner of the business from quoting to delivery, from the front office to the shop floor, and has become nothing short of a lifeline for day-to-day operations.

From ERP Frustration to Workflow Freedom

Many manufacturers rely on ERP systems to manage core functions, but GH found that traditional ERP tools weren’t agile enough for their needs. They needed something faster, more customizable, and that didn’t rely on an already burdened IT team.

“Most places will say, ‘everything’s in SAP.’ I don’t hear that for us. I hear, ‘You go to HighGear. You get the information from HighGear. You do that in HighGear.’ It’s really become almost our lifeline.” Erica Franklin – Quality Assurance Manager

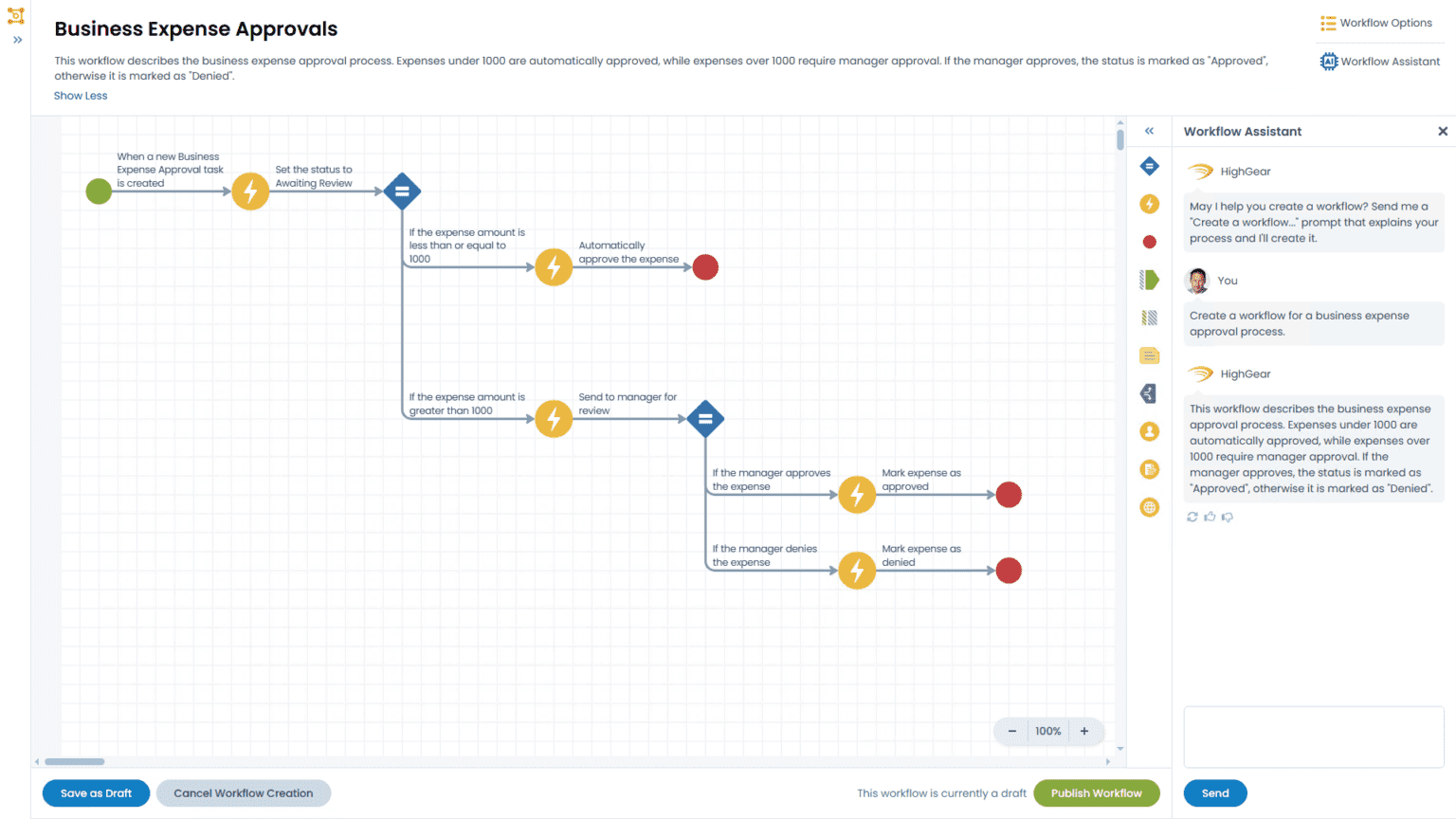

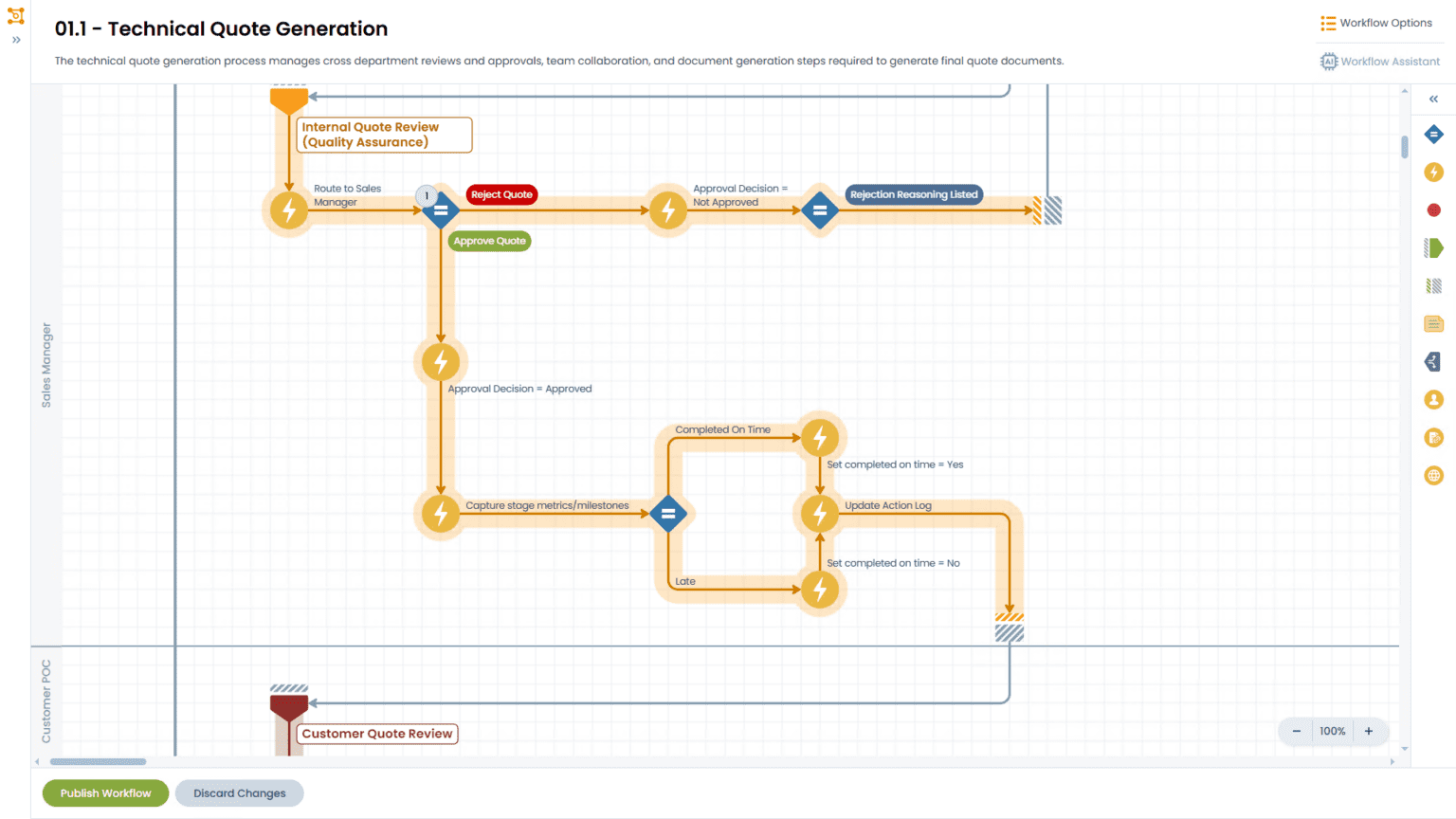

With JobTraQ, GH built workflows that mirrored how their teams actually worked. Without requiring months of development or outside consultants, they could digitize and evolve processes in days, not weeks or months.

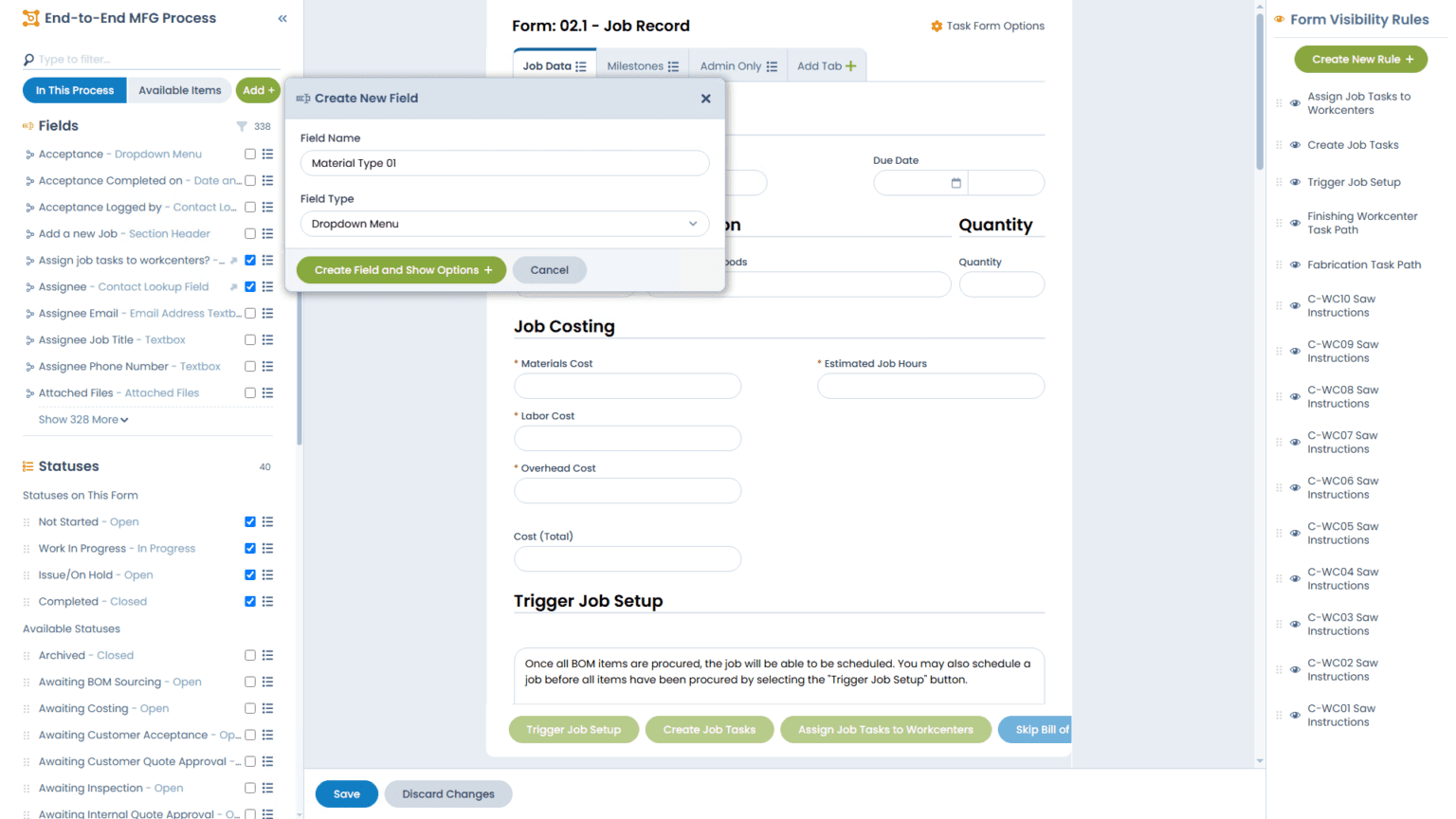

The Power of No-Code Customization

At the heart of GH’s transformation was JobTraQ’s limitless configurability. Users across departments could suggest improvements and see them implemented fast.

“If you can dream it or show them an example of what you think it should do, they haven’t been able to tell me no yet.” Danny Straatmann – Program Manager

Where process changes once took weeks or months to implement, JobTraQ let them launch improvements within hours or days, an essential capability for continuous improvement in fast-paced manufacturing.

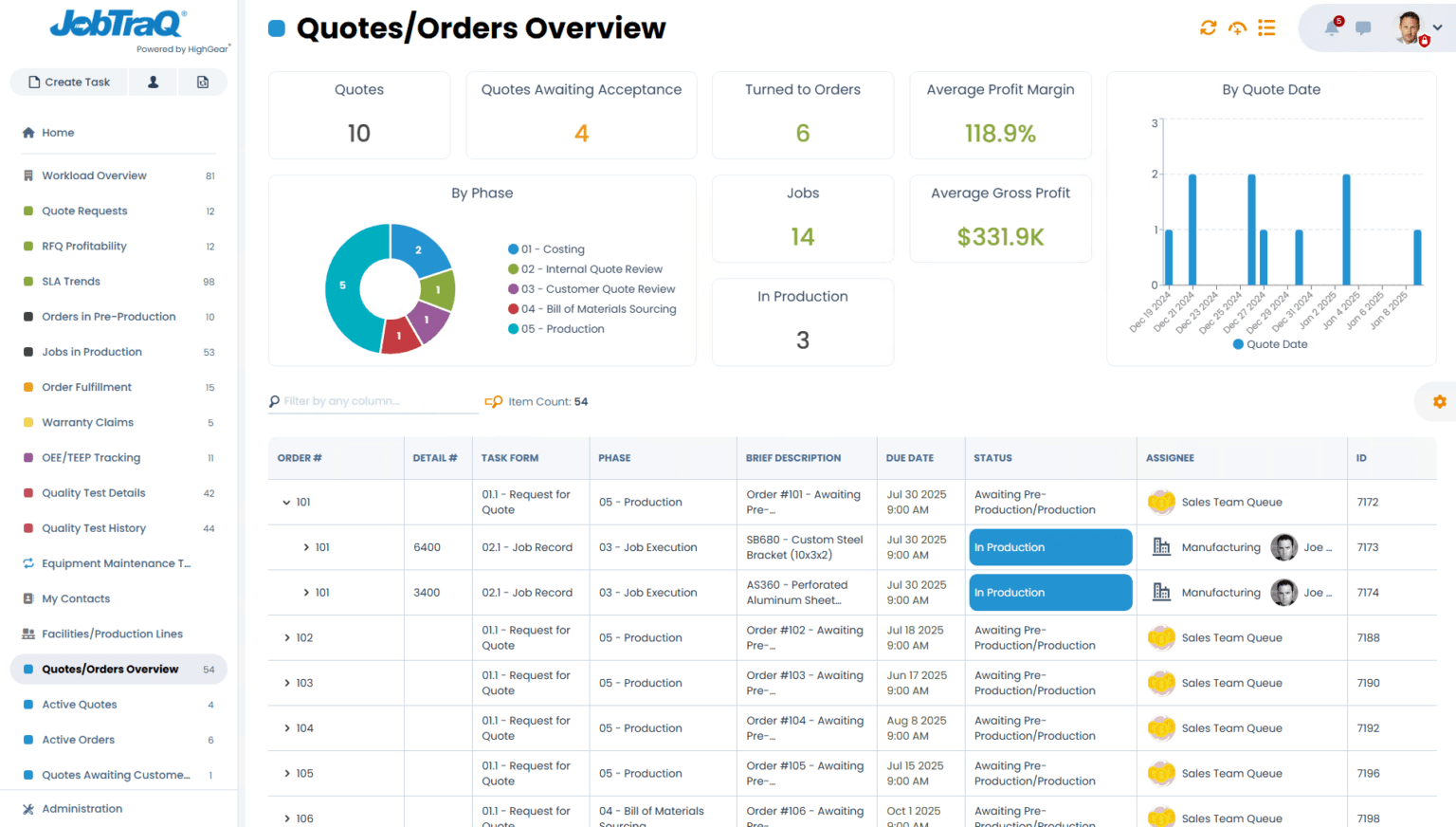

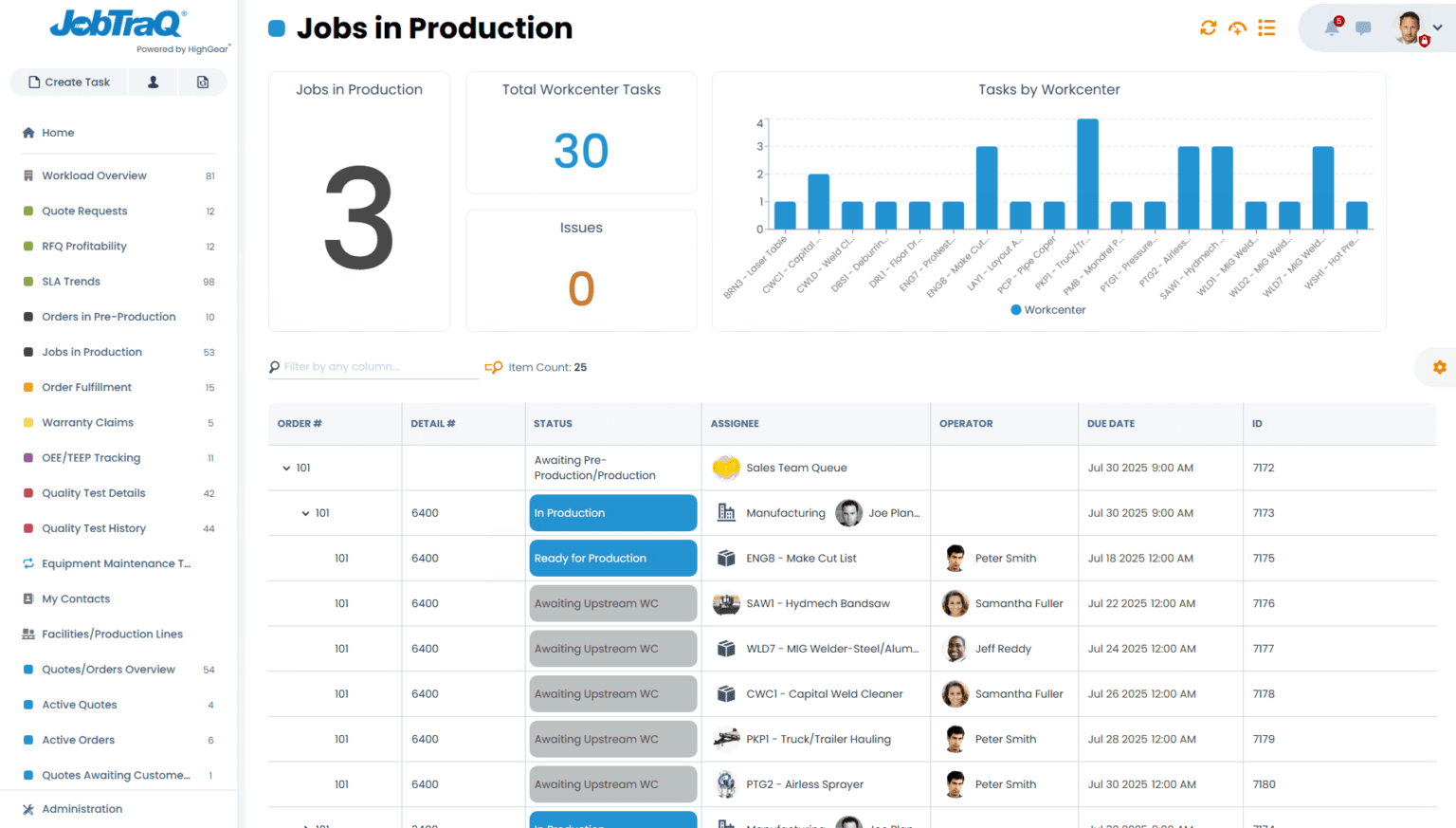

Visual Dashboards that Drive Daily Decision-Making

For GH, visibility wasn’t a nice-to-have – it was essential. And JobTraQ delivered.

“The reports are so easy. All the information is there. Very visual. I’m a very visual person. And those dashboards are huge.” Jorge Hernandez – Director of Sales and Business Development

Real-time dashboards now empower staff to track job status, review data trends, and resolve problems faster. No more chasing down spreadsheets or relying on tribal knowledge.

Knowledge Is Power and JobTraQ Makes It Actionable

GH uses JobTraQ to centralize and categorize operational data, making it easy to retrieve, trend, and analyze over time.

“HighGear allows us to quickly categorize data, retrieve it, track and trend information, and communicate within the company on operations, problems, potential improvements, productivity, maintenance work orders – it’s really what drives our business.” Patrick Green – President

Instead of hunting through files or guessing what happened last time, the team can rely on JobTraQ’s built-in audit trails and structured workflows to get clear, fast answers.

Compliance Without the Hassle: Built-In Audit Trails

Like many manufacturers, GH places high value on traceability and accountability. JobTraQ’s automatic audit logs give them peace of mind during every inspection, review, or customer visit.

“We’re big on people signing off and dating whatever they do. And there’s no fudging it, because as soon as you log in and do anything, it’s recording what you did.” – Elaine Homeyer – Technical Administrator

This level of traceability reduces risk, improves documentation integrity, and simplifies audit preparation across departments.

A Culture of Innovation Fueled by Workflow Agility

What makes GH’s success especially powerful is the cultural shift that followed JobTraQ’s implementation. Once employees saw how easy it was to modify and improve workflows, new ideas started pouring in.

“I wake up every day – much to the dismay of some of my HighGear admins – with a new idea for something I want to try. It’s exciting. And it makes the job fun.” – Patrick Green – President

Instead of a rigid software system, JobTraQ became a living framework for innovation – turning workflow design into a collaborative, empowering part of company culture.

Key Results from GH Tool & Mold

Based on the transcript, here are the primary outcomes GH experienced from adopting JobTraQ:

Impact Area | Result |

Visibility | Dashboards and reports give teams real-time access to key data |

Audit & Compliance | Automatic logging and accountability improve traceability |

Agility | Improvements deployed in hours, not weeks |

Culture of Innovation | Users actively suggest and implement new workflows |

Centralized Knowledge | All processes, data, and work orders tracked in one platform |

ERP Supplementation | Replaced legacy ERP use for day-to-day work management |

Why This Matters for Other HMLV Manufacturers

GH Tool & Mold’s story is not unique, but their success is worth emulating. Like many HMLV manufacturers, they:

- Needed more visibility without a full ERP overhaul

- Had limited IT resources and needed self-service configurability

- Wanted to reduce waste and improve response time

- Valued compliance and audit preparedness

JobTraQ delivered on all of that and continues to evolve alongside their business.

If you’re operating in a similar environment, GH’s results prove that workflow automation isn’t just for the enterprise – it’s for every manufacturer ready to grow smarter, not just bigger.

Learn More or Try It Yourself

Interested in seeing what workflow automation could do for your operations?

- Start a free 45-day trial of JobTraQ

- Talk to one of our workflow consultants about how to get started fast

- Watch the GH Tool & Mold video testimonial to hear the story firsthand